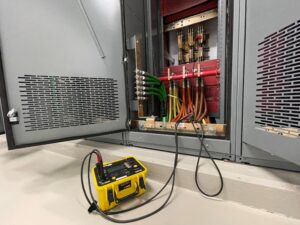

Acceptance Testing

As electrical systems, devices, and components become more complex, acceptance testing is crucial. We apply an integrated systems mentality to make sure devices not only function properly, but work together as needed. Through acceptance testing we:

As electrical systems, devices, and components become more complex, acceptance testing is crucial. We apply an integrated systems mentality to make sure devices not only function properly, but work together as needed. Through acceptance testing we:

- Identify damage due to impact, vibration, temperature and humidity variations, and other assaults encountered during delivery

- Conduct installation reviews and identify potential concerns before they become issues

- Verify that equipment, controls, and protective systems meet specifications

- Confirm that installed components are functioning and interfacing properly prior to being accepted and energized

- Evaluate controls and procedures that fall between specific trade responsibilities

- Recommend and guide corrective actions needed before equipment is placed into service

- Document procedures and results as a reference for future testing and preventative maintenance

- Operate our own testing equipment and analyze the data collected

We test medium and low voltage equipment such as:

- Batteries and charging systems

- Circuit breakers (air, molded case, oil, power, and vacuum)

- Ground fault protection systems

- Grounding systems

- High and low voltage cables

- Hospital equipment

- Instrument transformers (CTs, PTs, and CPTs)

- Lightning protection

- Motors and generators (electrical)

- Power Distribution Units (PDUs)

- Protective relays

- Remote Power Panels (RPPs)

- Substation apparatus

- Surge protectors

- Switchboards and switchgear

- Switches and disconnects (fusible, vacuum)

- Transfer switches (automatic, manual and static)

- Transformers (dry type, liquid filled, and pad mount)

- Uninterruptable Power Supply (UPS) systems

Test methods include:

- Infrared thermography

- Insulation power factor testing

- Insulating materials testing

- AC and DC high potential testing

- Contact resistance testing

- Primary/secondary current injection testing

- Ground impedance and soil resistivity