The discovery and harnessing of electricity changed the world more than any other invention. Unfortunately, electricity can be a serious workplace hazard, potentially causing severe employee injuries and property damage. In the United States, one person dies every day from an electrical incident. As a result, many companies need help creating a plan to protect their employees that includes the appropriate use of engineering controls, administrative controls, and personal protective equipment (PPE). This can be accomplished through a comprehensive electrical safety program.

What is an Electrical Safety Program?

An electrical safety program (ESP) is a documented system consisting of safety principles, policies, procedures, and processes that specifically direct activities appropriate for the risks associated with electrical hazards. An ESP aims to eliminate or significantly reduce the likelihood of injuries, disabilities, fatalities, property damage, operational disruptions, and associated costs while serving as a method for pursuing regulatory compliance and reducing legal liabilities. There are many standards, codes, rules, regulations, and guidelines related to an electrical safety program, including the Code of Federal Regulations (CFR), the National Electrical Safety Code (NESC), National Fire Protection Association (NFPA) standards, and the Institute of Electrical and Electronics Engineers (IEEE) standards.

What are the Nine Key Elements of an ESP?

The focus of an ESP is preventing or lessening the likelihood of electric shock, arc flash, and arc blast incidents with electrical equipment. There are nine key elements of an effective ESP, including:

- Conducting an initial needs assessment

- Developing a written electrical safety program

- Performing arc flash incident energy and hazard assessments

- Developing one-line diagrams

- Providing arc flash labeling

- Training and qualifying employees

- Supplying arc flash PPE via a specific program and methodology

- Utilizing insulated equipment and voltage-rated tools

- Implementing predictive and preventive maintenance programs and mitigation solutions

These nine key elements are typically developed and implemented in sequence; although, there is often overlap in terms of timeframes, especially throughout the program’s life cycle.

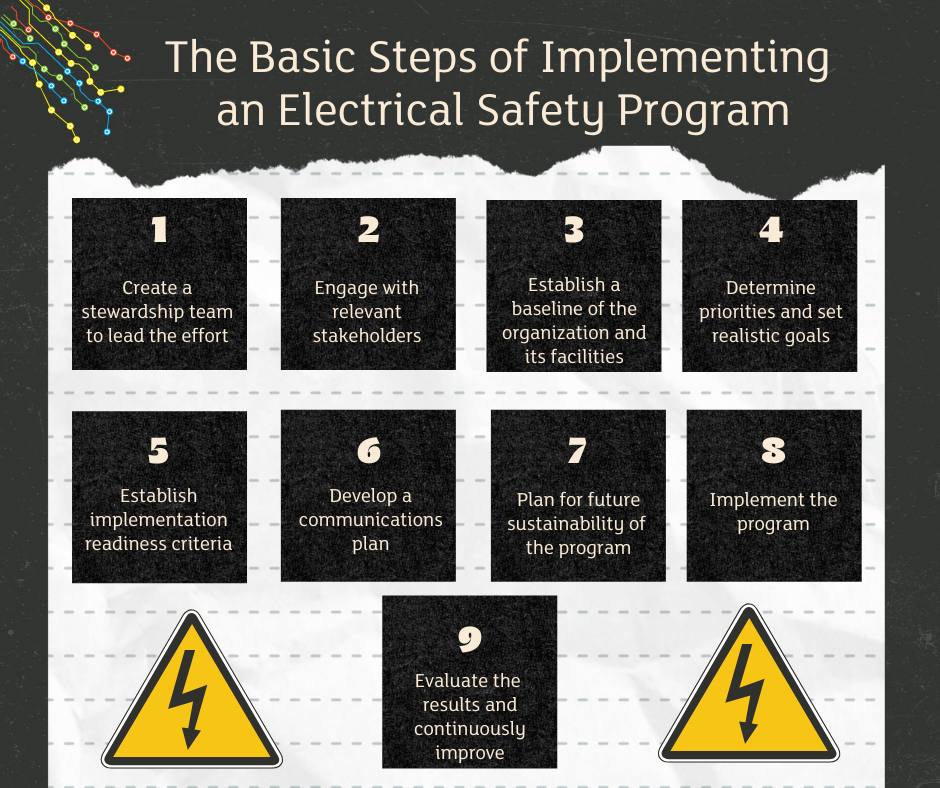

What are the Basic Steps of Implementing an ESP?

A comprehensive electrical safety program requires planning, budgeting, measuring, and evaluation like any other management process. The following steps will provide the groundwork for safety improvements, benefiting your facility long into the future:

Final Thoughts

Technical expertise in safety and electrical engineering are necessary to develop, implement, and maintain a comprehensive Electrical Safety Program. At P&D, our safety professionals have an established track record of designing and delivering customized safety programs based on client needs, current regulatory standards, and industry-based best practices.

Need help with your ESP? Contact us to discuss developing a custom-tailored ESP to keep your employees safe.